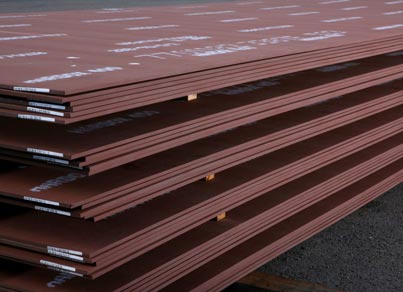

Hardox® BQ plates are a specialized type of wear-resistant steel plate manufactured by SSAB, designed for applications where high strength and durability are critical. The "BQ" in Hardox® BQ stands for "Blast Quenched," indicating a quenching process that enhances the plate's toughness and resistance to abrasion. These plates are known for their exceptional hardness, making them ideal for industries such as mining, construction, and heavy machinery, where materials are exposed to harsh wear and tear.

Hardox® BQ plates offer excellent weldability and formability despite their high hardness levels, enabling easy fabrication without compromising strength. They are commonly used in the production of dump truck bodies, excavator buckets, crushers, hoppers, and other equipment that must endure extreme wear. The plates are available in a range of thicknesses and grades, allowing for flexibility in meeting specific operational requirements.

In addition to their wear resistance, Hardox® BQ plates exhibit superior impact resistance, even at low temperatures, ensuring reliability in challenging environments. These plates are highly valued for extending the lifespan of equipment, reducing maintenance costs, and increasing overall productivity in demanding applications. With a combination of high performance and versatility, Hardox® BQ plates are a popular choice in sectors requiring resilient and durable materials.

Grades of Hardox BQ Plates:

★ Hardox 400 BQ: Offers a nominal hardness of 400 HBW for moderate wear applications.

★ Hardox 450 BQ: Slightly harder with 450 HBW hardness for applications requiring higher wear resistance.

★ Hardox 500 BQ: 500 HBW hardness suitable for severe wear applications, commonly used in mining and heavy construction.

★ Hardox 550 BQ: 550 HBW for applications requiring even more wear resistance.

★ Hardox 600 BQ: Ultra-high hardness of 600 HBW, designed for extreme wear conditions.

★ Hardox Extreme: Provides superior hardness and wear resistance for the toughest applications, with up to 650 HBW.

Standard Sizes:

★ Thickness: Ranges from 4 mm to 160 mm.

★ Width: Usually available from 1000 mm to 3350 mm.

★ Length: Typically ranges from 2000 mm to 14630 mm.

| Grade | Thickness (mm) | Hardness (HBW) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Impact Toughness (J) | Applications |

|---|---|---|---|---|---|---|---|

| Hardox® 400 BQ | 4 - 130 | 370 - 430 | 1000 - 1250 | 900 - 1050 | 10 - 15 | ≥ 45 at -40°C | Dump truck bodies, mining equipment |

| Hardox® 450 BQ | 3 - 80 | 425 - 475 | 1250 - 1400 | 1100 - 1250 | 10 - 15 | ≥ 27 at -40°C | Buckets, crushers, demolition tools |

| Hardox® 500 BQ | 4 - 32 | 480 - 540 | 1400 - 1600 | 1200 - 1400 | 8 - 12 | ≥ 27 at -40°C | Heavy-duty machinery, recycling equipment |

| Hardox® 550 BQ | 10 - 50 | 525 - 575 | 1450 - 1650 | 1250 - 1450 | 7 - 11 | ≥ 27 at -40°C | Wear parts in quarrying, mining, and cement |

| Hardox® 600 BQ | 6 - 65 | 570 - 640 | 1600 - 1800 | 1400 - 1600 | 6 - 10 | ≥ 20 at -40°C | Cutting edges, blades, high-wear surfaces |

| Hardox® HiTuf | 40 - 160 | 310 - 370 | 850 - 1000 | 700 - 850 | 15 - 20 | ≥ 40 at -40°C | Heavy wear and impact environments |